SteelArchives

Metallurgy

30/01/2022

SteelArchives | Information on materials, gold.

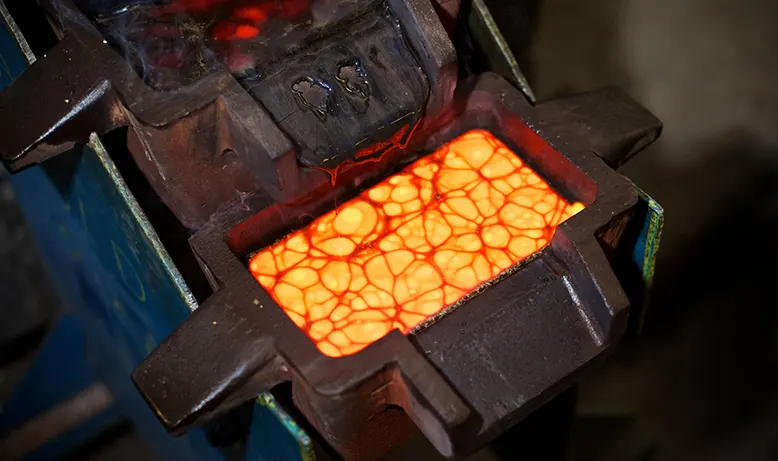

Gold metallurgy is generally carried out in two stages, solution mining and extraction from gold solutions, followed by refining of the metal. Prior to this, phase separation operations are carried out to eliminate troublesome mineralogical phases. The solution process is most frequently carried out by cyanidation, and extraction by cementation or adsorption on activated carbon. In theory, the detoxification of effluents and tailings, and possibly the destruction of cyanides, are carried out under strict control, proven methods exist and only need to be followed.

few informations on goldGold metallurgy is based in most cases on solution mining and extraction from gold solutions, followed by refining of the metal. However, pre-treatment operations based on mineralogical phase separations are often carried out in order to increase the grades of the raw ore by removing sterile or troublesome phases prior to metallurgy. The concentrates are then treated by hydro or pyro-metallurgy. Amalgamation, a very old technique, is now only used in small-scale operations. It is responsible for serious pollution and mercury poisoning. Most of the time, hydrometallurgy consists of dissolving the raw ores in heaps or in stirred reactors with cyanide, with extraction of the gold by cementation or adsorption on activated carbon. The gold is then re-extracted and refined. Effluent and tailings are detoxified. Contrary to popular belief, hydrometallurgy based on cyanidation is not a source of danger because the control and destruction of cyanides is a constant concern for the operator. Proven methods exist, but they must be implemented without interruption during operation and after the operation is shut down.

Gold brazing

Brazing gold can be similar to soldering, although the melting temperature is very low, making it look like brazing. It is essential that the edges of the parts to be soldered are joined and well aligned. Before heating the gold object with a soldering lamp or oxygen-acetylene torch, degrease it once with acetone, pickle it with nitric acid and then cover both edges with a flux suitable for gold. By concentrating the heat on the part to be joined, the joint is made in a few seconds without filler metal and leave to cool to room temperature.

Here is an article about zinc