Hot rolling.

Rolling a mass of

metal means flattening, deforming and thinning it.

This is done with the help of

machines, the rolling mills, equipped with rollers.

The

metal is heated in a furnace to make it easier to work. Then it is repeatedly crushed between the rolls of the rolling mill.

When it arrives, it has become a strip of sheet

metal, as shown in the diagram.

Example: A 10m long, 2m wide and 25cm thick plate comes out of the rolling mill as a sheet of the same width, over 1km long and 2mm thick.

What is forging and the forging professions?

Forging

metal means giving it a precise shape using a mould, called a die.

Forging is generally done while hot, using a

machine, press, or a drop hammer.

Under its pressure, the

metal, brought to the red takes the required shape.

This is how large or small

metal parts are made. For railways, cars, planes, taps.

Of course, the old-fashioned blacksmith still exists: with a large hammer, pincers and claws, he handles the iron that he has just red-hot.

On the anvil, he flattens points, rolls up scrolls, makes a horseshoe.

In industry, the situation is different: forging is done in automated

machines.

And the study of

metals and their resistance to deformation is done on computer.

Before being forged, the parts are produced by simulation.

How is steel deformed?

Deforming

metal means giving it a particular shape for its future use.

This is done with the help of

machines that apply different techniques.

Bending.

Rolled

metal is either bent or rolled.

It is bent to form more or less acute angles, for example for

metal cabinets. It is rolled to form pipes.

Stamping.

Stamping means forming a hollow object by stretching it. Let me explain.

The

metal plate is placed on a die which has the shape of the object to be made in the hollow.

Above this, an adjusted punch hits the plate. So that it fits perfectly into the recessed shape. The shape of a car wing, for example.

Stamping

metal means giving it a particular shape and relief by compressing it. With the help of two dies.

One that receives the

metal, the other that strikes it.

When the stamping is finished, the piece is made and the relief is printed on both sides. This is how coins are made, for example.

Stretching.

Stretching a piece of modelling clay means transforming it into a more or less thick coil.

With

metal, it's the same thing, except that it takes a lot more force.

This is why

metal is prepared, e.g. a thick wire is used to make a thinner wire.

Removal of material.

In order to manufacture certain parts, it is necessary to remove material, which is called machining. Here is an overview of the possible techniques.

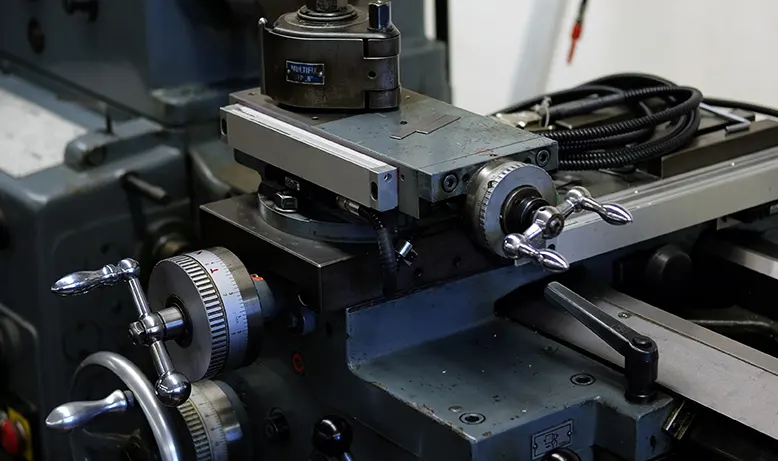

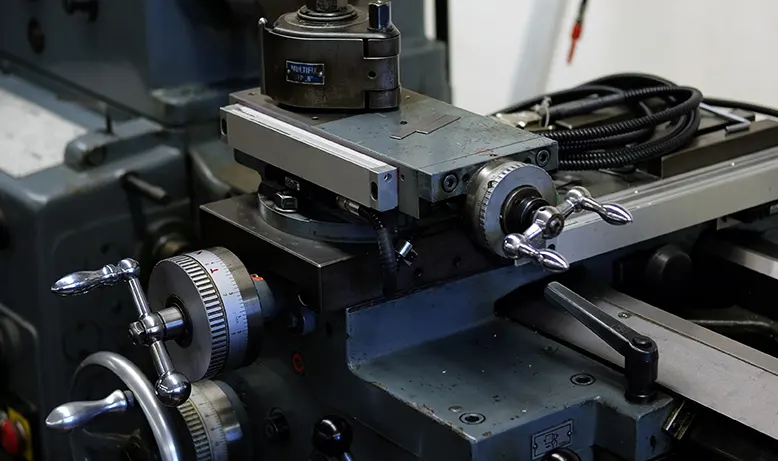

Turning, which allows cylindrical or conical parts to be

machined one by one on a

machine called a "lathe".

Placed in the jaws of the lathe, the part turns on itself. It is

machined by a tool, the advancing cutter.

The parallel lathe is the most common

machine tool. It is used to make pistons and cylinders.

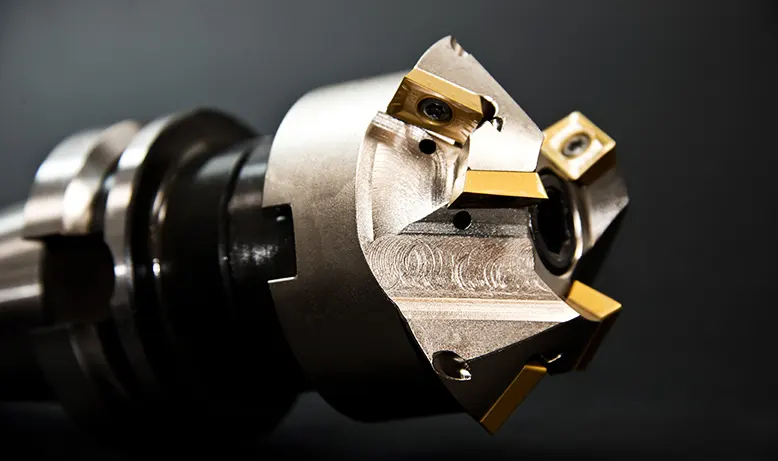

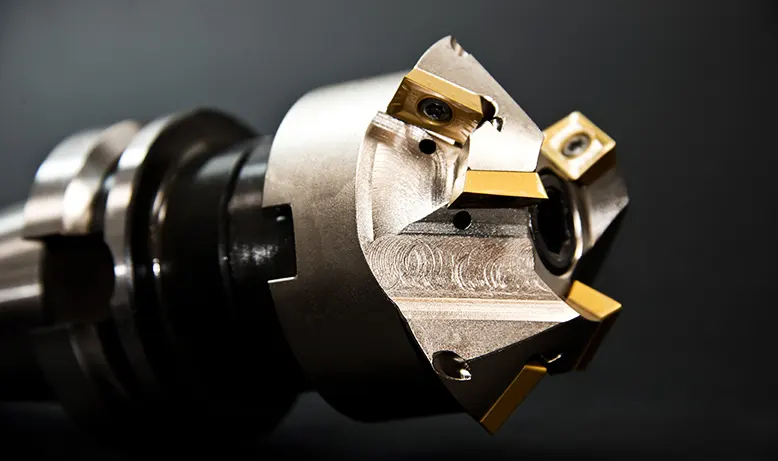

Milling.

The

metal plate moves under a milling cutter tool which rotates on itself.

This milling cutter, which has sharp teeth, cuts and scores the

metal.

Grinding.

Grinding a

metal part means giving it very precise measurements and a very clean surface.

This finish is achieved by rubbing the

metal finely with a grinding wheel.

In the case of surface grinding, the workpiece is placed under the grinding wheel, which scrapes and rubs the surface of the workpiece.

Polishing.

For the final finish. One possible technique is to place the

metal parts in tanks filled with abrasive elements.

Then the tanks vibrate, the parts and elements rub against each other. This is what polishes.

Turning.

It provides the small parts without which nothing would work, not the car, not the door handle, not the pen and so on. In short, screw-cutting is indispensable.

What's more, it is very practical, as it enables us to

machine parts in series, starting from a

metal bar.

This work is of course carried out in a

machine that is specially programmed for each part.

In the beginning, as you can imagine, this was not the case, in the 18th century, when screw-cutting was invented, it was to manufacture screws on a lathe.

This was already a great step forward. Until then, screw threads were made with a chisel.

It was for the watchmaking industry that industrial screw-cutting was born.

But it only reached its true cruising speed after the invention of specialised

machine tools.

Around 1870. From then on, they made mass production possible.

In order to manufacture certain parts, it is necessary to remove material, which is called machining. Here is an overview of the possible techniques.

Turning, which allows cylindrical or conical parts to be machined one by one on a machine called a "lathe".

Placed in the jaws of the lathe, the part turns on itself. It is machined by a tool, the advancing cutter.

The parallel lathe is the most common machine tool. It is used to make pistons and cylinders.

In order to manufacture certain parts, it is necessary to remove material, which is called machining. Here is an overview of the possible techniques.

Turning, which allows cylindrical or conical parts to be machined one by one on a machine called a "lathe".

Placed in the jaws of the lathe, the part turns on itself. It is machined by a tool, the advancing cutter.

The parallel lathe is the most common machine tool. It is used to make pistons and cylinders.

The metal plate moves under a milling cutter tool which rotates on itself.

This milling cutter, which has sharp teeth, cuts and scores the metal.

The metal plate moves under a milling cutter tool which rotates on itself.

This milling cutter, which has sharp teeth, cuts and scores the metal.

It provides the small parts without which nothing would work, not the car, not the door handle, not the pen and so on. In short, screw-cutting is indispensable.

What's more, it is very practical, as it enables us to machine parts in series, starting from a metal bar.

This work is of course carried out in a machine that is specially programmed for each part.

In the beginning, as you can imagine, this was not the case, in the 18th century, when screw-cutting was invented, it was to manufacture screws on a lathe.

This was already a great step forward. Until then, screw threads were made with a chisel.

It was for the watchmaking industry that industrial screw-cutting was born.

But it only reached its true cruising speed after the invention of specialised machine tools.

Around 1870. From then on, they made mass production possible.

It provides the small parts without which nothing would work, not the car, not the door handle, not the pen and so on. In short, screw-cutting is indispensable.

What's more, it is very practical, as it enables us to machine parts in series, starting from a metal bar.

This work is of course carried out in a machine that is specially programmed for each part.

In the beginning, as you can imagine, this was not the case, in the 18th century, when screw-cutting was invented, it was to manufacture screws on a lathe.

This was already a great step forward. Until then, screw threads were made with a chisel.

It was for the watchmaking industry that industrial screw-cutting was born.

But it only reached its true cruising speed after the invention of specialised machine tools.

Around 1870. From then on, they made mass production possible.